Required Texts for Holley Sniper EFI Installation Tips

Ok, any decent course is going to require a few texts. The good news is that these don't cost you anything! If you don't already have them, Please download the following PDF files:

Owners & Installation Manual

Holley Sniper EFI System

Quickstart Manual

Holley Sniper EFI System

Sniper Installation Manual Review

Quickstart Manual Notes

I figured we would start our review with the Quickstart Manual and then go into details later in the full Installation Manual. A few things caught my eye here that I would point out. I'm not trying to re-write the manual, just pointing out a few things that catch my eye.

"Engine is a naturally aspirated (no supercharger, turbocharger, etc.) V8". Ok, the reasoning on the "no boosting allowed" requirement is simple: The Sniper's MAP is only set up for atmospheric pressure. If you bought this system and had plans to boost it then it is absolutely not going to work. The Terminator EFI can conceivably work, but that is because a professional EFI tuner can attach a laptop and the Holley EFI software and make the necessary adjustments (after upgrading the 1-bar MAP sensor, of course.)

I suppose the "V8 only" should not be surprising. After all, the Terminator has the same limitation (assuming you want to use the Startup Wizard functionality.) Don't buy this system if you had your heart set on putting it on your 6 cylinder engine. You're going to need to opt for the Terminator and have it custom programmed for 6 cylinders.

"Factory dual plane intakes will require an adapter (PN 17-6)" - I wrote a piece a while back that suggested that the Terminator required a spacer if used on a dual-plane manifold. That elicited a phone call from Holley Engineering who explained I was absolutely wrong about that. Rather than set myself up for another phone call, I'll just say that sometimes enhanced performance can be gained by adding an air gap to a dual-plane manifold (regardless of the fuel induction system.) However, I'm not sure why they are recommending a square- to spread-bore adapter. I would instead humbly suggest a standard spacer, or grinding an air gap into the center of the dual plane flange mating surface. Not because the Sniper needs it. Just saying.

"Holley strongly recommends an in-tank pump". Okay, I kind of have to chuckle at this one. The Sniper Master Kit includes an inline fuel pump. Don't get too wrapped up on this one. Yes, an inline is going to make a little more noise. It's also far easier to install. Worst case, use a good Walbro 255 LPH inline fuel pump to get the system running, and then install it in the fuel tank later if it's too loud for you.

Key Component Installation Notes

Ignition Hookup

Like it's higher-end predecessors, the Sniper EFI system can control ignition timing. That is a great thing because it really goes a long way in making engines with long-duration cams behave well at idle. We echo Holley's recommendation to first start the engine without Ignition Timing Control. While it is absolutely advantageous to allow the Sniper to control timing, first get the engine running with the existing ignition system (assuming you have a working ignition system.) Adding the ignition is not rocket science, but why complicate matters?

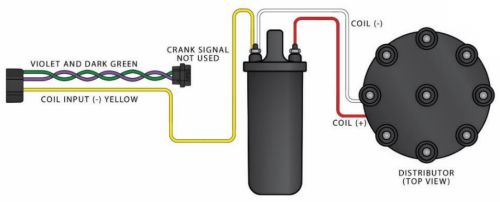

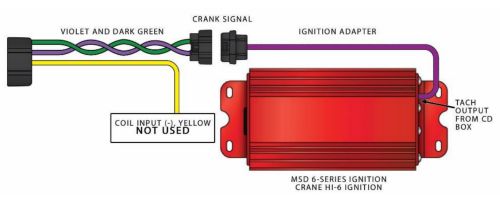

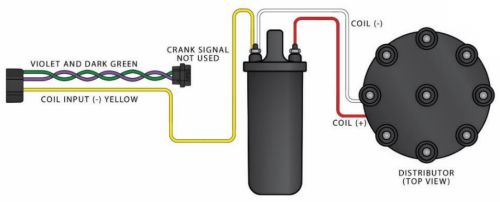

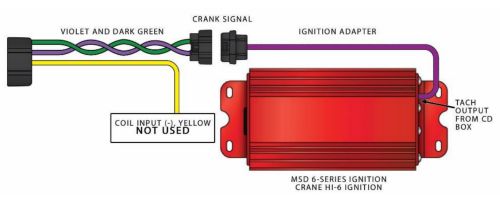

Sniper Ignition Setup without Timing Control: Here you are simply providing an RPM signal so that the Sniper can accurately fuel the engine. This signal can come from either of two sources. If you have an capacative-discharge box that has a tach-out signal on it, then that is the way to go. The Sniper kit includes a purple wire that allows you to connect to the tach out terminal on the CD box and plug directly into the crank signal harness on the Sniper. In the event you only have a coil and distributor, no problem. Connect the yellow-wire on the 7-pin connector from the Sniper to the Coil (-). Choose one of these methods initially.

Sniper Ignition Setup without Timing Control: Here you are simply providing an RPM signal so that the Sniper can accurately fuel the engine. This signal can come from either of two sources. If you have an capacative-discharge box that has a tach-out signal on it, then that is the way to go. The Sniper kit includes a purple wire that allows you to connect to the tach out terminal on the CD box and plug directly into the crank signal harness on the Sniper. In the event you only have a coil and distributor, no problem. Connect the yellow-wire on the 7-pin connector from the Sniper to the Coil (-). Choose one of these methods initially.

Choose from ONE of these setups. NEVER HOOK TO COIL(-) WHEN USING A CAPACITIVE DISCHARGE IGNITION BOX!

Sniper Ignition Setup with Timing Control: Once you are up and running then press on for timing control. There are two ways to go here. Option 1 is to purchase and install one of the Holley EFI Dual-Sync Distributors on your engine. An adapter harness is available to connect this distributor directly to the Sniper EFI throttle body. A straight-forward setup process is detailed in the full installation manual. For best results, use the optional Dual-Sync Distributor to Sniper EFI Connector Harness.

If you have a GM or Ford application and already have an MSD magnetic distributor, Option 2 is a good choice. In this option, you replace the existing rotor with the MSD 84211 Rotor Phasing Kit. By locking out the mechanical and vacuum advance and adding this inexpensive kit, you allow the Sniper to control the timing. There are quite a few steps to correctly installing the ECU-controlled timing setup using the rotor phasing kit but the end result is a top-notch computer-controlled ignition for a very reasonable price.

An ignition coil driver (Holley Internal PN 271R1165A, PN 556-150) is included in the Sniper kit and is required to run the Sniper with timing control if no MSD ignition box is used. (The MSD ignition box acts as the coil driver when implemeting timing control.) It is noteworthy that timing control is only possiblle with an external coil. If you have an MSD GM Small Cap HEI distributor you will need to replace that with a distributor that uses an external distributor. To my knowledge, it is not possible to use a factory GM small cap HEI distributor with the Sniper doing timing control.

The Holley Dual-Sync Distributor, MSD Rotor Phasing Kit, the Sniper Coil Driver Module and the Holley EFI Dual-Sync Distributor to Sniper EFI Connector Harness:

Fuel System Hookup

One of the "value added" features of buying here at HolleyInjection.Com is that we are going to have a technician speak with each buyer (or hir or her mechanic) to identify any additional components that might be required for the installation. We want to make sure that when you get your system that you're not having to do a bunch more shopping before you can start the installation. The fuel system is a good example of this.

The easiest answer on the fuel system is to buy the Sniper with the Master Kit, which includes pump, hose, fittings, filters, and fuel bulkhead. But sometimes that is not practical and that's where we want to help you engineer your system. Maybe you want an in-tank fuel pump--in some cases this is a fairly easy option. Or maybe you have the fuel pump already and simply need some other components. We keep in stock and offer all of the fuel system components "ala carte", wo we can get you exactly what you need.

The Sniper has -6 AN male inlet and return fittings. This is an excellent feature because you can plumb with -6 AN hose ends or we have adapters for nearly any sort of connector you might want to use. In general we recommend 3/8 inch hose barbs and EFI-rated fuel hose. This is fully adequate, completely safe, and the lowest cost option. Of course, nothing is quite as sexy as a full-up AN-plumbed engine, but the cost goes up dramatically. Let us help you source whatever fits your budget and your taste.

Ok, as I said at the top, this course is going to be a work in progress (and that's all the progress I can make today!) I will gladly address your points of concern--just add them below!

Click here to read more articles from Chris about the Sniper EFI System!

Sniper EFI+

Sniper EFI+

Terminator X TBI+

Terminator X TBI+

Terminator X MPFI+

Terminator X MPFI+

HP-Dominator EFI+

HP-Dominator EFI+

EFI Components

EFI Components

Sniper Ignition Setup without Timing Control: Here you are simply providing an RPM signal so that the Sniper can accurately fuel the engine. This signal can come from either of two sources. If you have an capacative-discharge box that has a tach-out signal on it, then that is the way to go. The Sniper kit includes a purple wire that allows you to connect to the tach out terminal on the CD box and plug directly into the crank signal harness on the Sniper. In the event you only have a coil and distributor, no problem. Connect the yellow-wire on the 7-pin connector from the Sniper to the Coil (-). Choose one of these methods initially.

Sniper Ignition Setup without Timing Control: Here you are simply providing an RPM signal so that the Sniper can accurately fuel the engine. This signal can come from either of two sources. If you have an capacative-discharge box that has a tach-out signal on it, then that is the way to go. The Sniper kit includes a purple wire that allows you to connect to the tach out terminal on the CD box and plug directly into the crank signal harness on the Sniper. In the event you only have a coil and distributor, no problem. Connect the yellow-wire on the 7-pin connector from the Sniper to the Coil (-). Choose one of these methods initially.

27 Comment(s)

I am swapping out a LS1 motor in my 2002 Camaro Z-28 for a LS376/525 GM crate engine. I am using the stock ECU from the LS1 2002 Camaro, with the 24-58 reluctor converter, injector adapters and needed sensor conversions, Texas speed and performance has done the basic tune. The motor has a competition balancer that scavenges a few hp, cold air induction by SLP,85mm maf by granatelli, 92mm cable driven TB, 4l60E tranny with new valves and shift kit, 3400 rpm stall converter, larger tranny pan by 5 quarts and a cooler, 373 rear end gears, dual 3" exhaust with dual cats and electric cutouts after cats, and some sticky Nitto street drag tires, suspension , brakes and torque arm, chassey are all upgraded.

Soooooo, why do I need to buy your product ? Convince me ? Tell me how this purchase makes sense.

I love your question! :-) Be sure that we never try to convince someone that they need something unless we ourselves, in the same situation, would be convinced that it is the right thing to do. And in your situation the Sniper EFI system is not at all what we would recommend.

Instead, I would recommend that you consider the Terminator LS systems. Even then, I recommend it with a caveat. If you get this new engine installed and the "basic tune" that was provided works great then I would delay the purchase. But someday you're going to want to do more. You might want to run Nitrous. As a minimum you're going to have to have the stock ECU re-tuned. It is likely you will have to run a more-expensive wet-nitrous system. You will have to invest in a nitrous controller. If you had the Terminator LS you could run dry nitrous and program multiple stages of progressive nitrous--for no additional cost.

Or say that you want to adjust your shift points. Do you really want to take your stock ECU to a tuner every time you want to play with that? Or maybe you want to boost the engine. The ECU used in the Terminator allows you to do boost control Or add traction control. Traction control does take an add-on box, but it is far less expensive than the complete Davis Traction Control system because it uses the brains of the Terminator.

I've only touched on the features that are basically "standard" with the Terminator LS but either require a new tune on the stock ECU or are completely impossible. And it's completely plug-and-play with your engine. I suppose it depends on if you are taking the long or short view of your project. If you are taking the short view, trying to get it to run and then sell it, stick with what you have. If this is something you plan to own and grow over time? Switch to the Termaintor LS early in your game plan.

Here is a link. Check it out. You would want a system that provides transmission control. http://www.holleyinjection.com/terminator/terminator-ls

I talked to the Holley fuel injection engineers at SEMA today. I confirmed that the sniper WILL NOT work with any GM distributer if you want timing control. I'm not happy at all about that because the Holley 4Di I'm replacing used my computer controlled HEI for timing control. My best option is to buy a MSD distributor part #85551. Some good news, my 4Di fuel pump will work with the sniper. More bad news, the sniper's air cleaner flange is 1" higher than the 4Di, so my Corvette hood With rpm air gap manifold will not close. After 15 years with the 4Di, I really want self learning. So maybe I'll go back to a low rise manifold and centrifugal/vacuum advance HEI. Dang it!

Thanks for confirming with the engineers what we discussed on the phone yesterday, Bernard. I was pretty confident that using the GM distributor to do timing control was not an option for the Sniper. And I agree that is a bit of a surprise since the GM Small-Cap HEI is and has been the go-to distributor for the Holley EFI product line.. Glad that the 4Di fuel pump will work. That simplifies things quite a bit though!

Sorry that it's going to require a shorter intake manifold to fit on your Corvette. I suppose there had to be some concessions to get all of the electronics into the throttle body housing. I'm excited that you're sticking with it, though. Your Sniper kit should be arriving in a couple of days. Let me know where I can be of assistance!

Can your performance parts supplier provide EFI system technical support like this?

If not then you should be buying from EFISystemPro.Com. Remember, no one is as passionate about or as able to guarantee the success of your EFI project as EFISystemPro.Com!

I spent Turkey weekend removing my Holley 4Di FI, tons of wiring and sensors, and installing my new sniper, way much less wiring. The handheld computer display takes some practice and setting up. Have your startup procedure in your lap when you first power it up.

As advertised, the car started right up! The car overheated quickly and I had to shut it down. You have to tell the computer that you want it to operate the fans. There are default on and off temperatures, but the default doesn't switch the fans on.

Once I solved that problem, I noticed a weeping leak from my 4Di Holley fuel pump. When I tightened the fitting, it got worse and I had a dripping leak. I'm going to get a new Walbro with -6 fittings on each end to solve that.

When I started the car again, it idled great, but when I gave it gas to rev the engine a little, it settled to a ridiculously high idle. I turned the idle screw out, and that seemed to help a bit, but the idle stayed high. I set the idle at 900 rpm in the handheld, but whenever I exercise the throttle, the idle is way too high. It's as if there is a tremendous vacuum leak. I used the unused plug in the front of the throttle body for my PCV vacuum source. The instructions don't say anything about the PCV source, but I assumed this location was ok. Am I wrong? what else could be causing the high idle? The throttle position returns to zero, but the idle is way too high, even after adjusting the idle screw. What am I doing wrong?

I won't drive the car until I get the new fuel pump in, so no report on driving yet. Suggestion number 1, the handheld display should have a holder for the stylus. BTW, can I get another stylus please.

Bee Jay

Wow--thanks for the detailed report, Bee Jay! Sounds like you did a great job on the installation.

The Sniper has some advanced tuning features that should allow you to get the idle under control. These tuning features are all accessed using the handheld controller. There is a basic idle speed setting (search for "Tuning : Basic : Basic Idle" in the installation manual) but I think you will find that it is already far below the idle level at which you are currently running.

if you search the manual for "Tuning : Advanced : Adv. Idle" you will see a whole host of settings that can be adjusted. Rather than just trying them all, I'd recommend that you take a look at "IAC hold position". In a few cases if this is too high then it won't allow the engine to idle down enough for the idle air control circuit to have effect. Try turning this down a bit and note if there is a change. Also look at the "IAC startup hold time"--it can have a similar effect. In any case, always note the original setting so you can go back to the original settings if necessary.

Your point about the need for a holder for the stylus is well taken. We'll get a new stylus on the way ASAP. Thanks!

Can your performance parts supplier provide EFI system technical support like this?

If not then you should be buying from EFISystemPro.Com. Remember, no one is as passionate about or as able to guarantee the success of your EFI project as EFISystemPro.Com!

If your idle is way higher than what you entered in the basic setup, you may have to go to advanced idle setup. Take a peek at the "Idle speed curve". I had entered 900 rpm in the basic setup, and the curve was at 900 rpm at the coolest temperature only. The rest of the curve was set at 2000 rpm. You have to adjust each point down to 900 rpm. I don't know why my rpm curve was so high. I would think that if you input 900 rpm in the basic setup, the entire curve would automatically set to 900 rpm. I still haven't driven the car, waiting on a new fuel pump.

Also, you can't make changes with the engine running. The engine has to be "stalled", not running, with the ignition key on. After making changes to your program, you must turn the key off, and back on. Also, you really want to wait the full 2.5 seconds before cranking. The difference in the start is amazing. I wish there was a way to reduce the 2.5 seconds wait time. I'm not being negative, just sharing some things that would have been good to know.

Bee Jay

Right--as I said above! :-) The idle speed curve adjusts the target idle speed down as the engine warms up. However, what you are describing sounds like something got confused. I would simply use the touchscreen to gradually scale the idle speed down to your target at and above what you consider a normal operating temperature for your car.

Besides the idle speed curve take a look at the other parameters I suggested you consider in my separate email:

IAC Rampdown > IAC Hold Position: Note the original setting and then gradually lower this value.

IAC Rampdown > IAC Ramp Start: Note the original setting and then gradually raise the value.

IAC Rampdown > IAC Kick: Note the original setting and then turn this off entirely.

IAC Startup > IAC Parked Position (Cranking): Note the original setting and then turn this down gradually. (It needs to be open a little bit to crank so if it starts having trouble cranking then maybe you've lowered this too much.)

IAC Startup > IAC Startup hold time: Note the original setting and then turn this down gradually. This is what gives you a little additional RPM immediately after start.

I believe that 2.5 second delay is simply what is required to transmit all of the tuning changes across the bus. Being a serial bus, that is not instantaneous but hopefully 2.5 seconds isn't too painful. I'm not sure they can make the bits go down the wire faster so that delay may simply be unavoidable.

Can your performance parts supplier provide EFI system technical support like this?

If not then you should be buying from EFISystemPro.Com. Remember, no one is as passionate about or as able to guarantee the success of your EFI project as EFISystemPro.Com!

I just did a Sniper install on my Chevelle a few weeks ago. You do not use, or need, the Sniper COIL DRIVER if using an MSD ignition box. Just a head's up. The coil driver is used, I guess, in place of the ignition box.

Excellent clarification, Bob--I've updated my post above based on your note!

Hey there, One more question for you. As always feel free to edit as required. So if you remember I'm installing the sniper on a 502ci trike. The distance between the frame rails will not allow me to orient the Sniper in the conventional way, front to back so to speak with linkages on left side. If I've done my research as well as I think I have and you have said how well rounded this unit is... Can I mount it 90 Degrees from normal, linkages facing forward. I have fabricated an adapter plate to re orient, and assume it will work as designed either way. I just need your confirmation. Do the injectors care which way they are oriented as long as the exhaust readings are where they need to be the Efi shouldn't care how it sits, correct? Thanks again, Jason

Since you have a single-plane manifold (as you mentioned separately) that will be no problem. But it would not work on a dual-plane manifold.

You see, there is a primary and secondary side to the Sniper. The basic idle is adjusted using the primaries. In a normal installation, one of the two primaries sits over each side of a dual-plane manifold, giving air to both planes. If you rotate the Sniper 90 degrees on a dual-plane manifold then only one side would get any air/fuel at idle. The IAC would add some air on the other side but even then that couldn't work. It probably wouldn't even work very well on a dual-plane manifold with a spacer, since the weight of the fuel might not make the sharp turn very well..

On a single-plane manifold, however, I can't think of a problem other than a strange orientation of the linkage, but I'm sure you are thinking about that in making this decision.

Chris, I have the sniper installed in a Sunbean Tiger with a 302. It runs great. I want to remove my MSD box from the equation and use the distributor as a trigger. Would you recommend it? In addition what should I time the distributor to once I lock it out? Right now I run 34 degrees total timing. I would like to lock out the distributor run it as is, set the timing and then hook the sniper in with the coil driver to handle it. Should this idea work?

Oooh...Sunbeam Tiger. Nice!

To clarify, I understand you to mean that you want to control the timing in your 302 with your Sniper EFI. Good choice, but I'd recommend going with the Holley Dual-Sync Distributor for the Ford 302 for all of the reasons that I mention in my article on Sniper Ignition Wiring.. (Note that the Ford 302 distributor stays on backorder so it's best to order one now and take advantage of our 5% off on orders that can't ship in one business day.)

You can certainly remove the MSD box if you'd like (the Sniper ignition article referenced above shows both with and without it) but I'd recommend leaving it unless you have a specific reason to do away with it. Just be sure to disable the rev limiter as that function is better controlled by the Sniper.

Unfortunately, doing Sniper ignition control with the stock distributor is not an option that is supported by Holley. Have fun with that Tiger!

Installed Holley Sniper EFI on my Ford 302, connection to the MSD6A tach out plug. All systems looked good, car started up fine, drove it around the neighborhood and put it back into the garage. Next day, car won't start. Looked at the ECU systems check, all sensors and fuel presure look good, except now I get no crank vallue. It stays at STALL, even when cranking. ???

Well, the only thing that is obvious is that the ECU isn't seeing a crank pulse. What would have changed that overnight is going to take some old-fashioned troubleshooting.

The first thing to do is look at the red diagnostic LED on the MSD6 box. If it is not flashing when you are cranking, check that the unit is correctly powered and the connection and signal coming from your crank signal source (distributor, crank trigger wheel, etc.)

If the LED is flashing then you have to check the connection and signal between the MSD6 box and the Sniper EFI ECU. I would start with a digital probe on the wire between the MSD6 tach out and the pin A of the 7-pin connector on the Sniper EFI. (You can also use a volt meter but a powered digital probe usually provides a much more visible confirmation.) Start by back-probing the connector on the Sniper (while cranking) and then continue forward to the connector on the MSD 6 box if nothing is found there.

I can't imagine what might have failed when the system was sitting overnight unless a wire got against something hot and has grounded itself. But if you patiently check your connections I think that you're going to find your problem.

Hallo. I have just installed a sniper on my ford 460 / c6. Tps=0 and iac= 4 , idle set to 580 rpm and it is running smooth , but when I step on the throttle in neutral it will take about 10-15 sekunds to return to idle ( 580 rpm ) is there any way to change that ? I have driving about 30 miles this morning and it is much better than the edelbrock 600 , so far I am very glad.

There are a few things we can adjust to et the idle to drop back to the target more quickly. However, unless someone experiences a problem that prevents them from driving I always recommend putting several hundred miles on the engine in a broad range of driving conditions so that it can learn as much as possible on its own before making any manual adjustments. Doing otherwise invariably either requires that the manual adjustment be changed later (after the tune is finished) or else results in a tune that compensates for the manual adjustment. It sounds like you have everything set up perfectly for learning so drive and see if the problem doesn't solve itself to some degree.

One thing to watch as your tune improves through self-learning is the IAC number. That number will normally drop a little bit. This is because the engine becomes more efficient and idles with less air, reducing the need for IAC. Unfortunately, that is going to actually increase the problem a little bit. If you see the IAC settle down to zero when the engine is fully warm you would want to turn your idle speed screw out (shutting the throttle plates) just a tiny bit. This will give the IAC more headroom to pull the idle speed down.

I have installed the sniper system on a 302 in a 64 ford f-100 with a c-4 automatic one of the issues I have is the system will not hold closed loop, and it will also learn up to about 22% and then it will start unlearning where it goes to a - deg learn % also it has an issue of starting off the start up screen, but if you go to any one of the gauge screens it will start and run?

There are a few conditions required for closed loop. If it is accelerating enough to experience acceleration enrichment, or if it is decelerating (as defined by 400 RPM over the idle and TPS at zero) then it will come out of closed loop. I've also seen cases where RFI noise inducted on the TPS will make the ECU think you are depressing the throttle and that will take it out of closed loop.

Regarding, the learn, I think you have a common misconception. The learn percent is not a percentage of completion as many think. 50% learn doesn't mean that you're half way there. Instead, it means that the ECU has "learned" that the base fuel map needs 50% fuel added at that particular RPM and manifold pressure. A negative learn means that the ECU has learned that fuel needs to be taken away at that point. So don't worry about that, it sounds like it's working well.

I'm not quite sure I follow the issue with the start-up screen, If it seems to be dysfunctional, get with the vendor where you bought the Sniper unit and see if a warranty clam is appropriate.

What spark plug will work best with ford Cleveland motor with Holley Sniper fitted. Thanks for your time Lez Australia

I get that question quite a bit. It turns out that whatever spark plug that is working for you now will certainly work fine with the Sniper EFI. In fact, you will probably find that the combustion is much more accepting of the fuel/air mixture provided by the Sniper EFI than that of the carburetor. The atomization is generally just a little bit better and ratios more consistent, leading to less rich spots in the RPM range and puddling of fuel in the intake.

I am installing a Sniper EFI on a 1992 Mustang 5.0L using a Holley dual sync distributor and an MSD 6AL CD box. My question is, "Do I need to wire up both the pink wire from the adapter (558-493) and the pink wire from the 7-pin connector to 12V switched ignition source?"

Yes--you need switched power to "turn on" the Sniper EFI System via the pink wire 7-pin connector (it doesn't draw any power from that but gets its power from the heavy-gauge red wire.) And you need to power the dual-sync distributor with the pink wire on the 558-493 adapter. You can usually draw these from the exact same key-on source.

installing sniper 550-511k system on 1968 lemans convertible has been updated to hei distributor just curiuos if any recomedations where the best place to connect the pink wire? instructions say 12 volts key on and while cranking and have looked up and seen other people using extra terminal in fuse block that i dont have so was curious what best place to connect

Great question--this trips folks up from time to time. I don't keep a black book with the best switched-on positions in all cars but I can give you some tips.

Finding a good source of switched power for the Sniper can sometimes be a real challenge in these older cars. You need a source that is on not only when the ignition switch is in the "on" position but also when it is in the "start" position. If you just get 12 volts in the "on" position everything will look great until you try to start it. But then your power to the Sniper EFI System will go out during starting. Surprisingly, it will sometimes "work" in this configuration, but not well. The Sniper primes the intake manifold with fuel when you key on, so the ignition fires and cranks the engine over. Sometimes the ket gets back in the "on" position fast enough for the Sniper to start up, recognize the engine is running, and start fueling the engine. But that' s definitely not what you want.

What you might try is diconnecting power to your starter and having an assistant hold they key in the "start" position while checking all of the terminals in the fuse box. When you find one that is hot during "start" then have the assistant let the key go back to "on". If you still have power then that might be a good candidate for your Sniper switched-on signal.

Thanks for your help! After a little more probing of fuse block and existing wires that i could tap into i finally found one that holds the 12 volts in on position plus in crank position. That circuit would be the turn signal flasher circuit (not flasher in fuse block) but secondary flasher for turn signals. I haven't driven the car yet but with getting through final install and letting run in the garage it seems to be working just perfect. Is there anything you can think of that will cause me a problem with using that circuit?

As long as you just added the pink wire from the Sniper to that circuit it should be fine. The pink wire draws almost no current so you won't overload a circuit with it. I think you're all set!

Looking to install the EFI on my 1977 Chrysler Newport 2-door hardtop. It's a 400ci car and it was originally a "Spark Control Computer" Car. It has had the spark control system disconnected, a vacuum advance distributor installed (pulling vacuum from the manifold) but retains a Thermoquad from the era. This setup isn't ideal and is prone to stalling under acceleration from stop. I think the Sniper EFI might a good fit to replace this setup. It's not a show car - it's just a nice old car we keep around but I'd like to improve the drivability as my wife is less forgiving of the odd stall than I am. Could I run this system without doing anything to the ignition side? Or would I have to replace the distributor to have this work?

If your existing ignition works with a carburetor then it will keep working with the Sniper EFI System. Even more, if there is an upgraded ignition available, the Sniper will work fine with it as well. The only thing the Sniper EFI system needs to run is an RPM signal, either from COIL(-) or from the tach output of the MSD box (if so equipped.)

I would expect that the Sniper would be a great choice on your 400 CI Chrysler engine. I would recommend installing it initially with the ignition you have now. Once you have that working well then we can talk you through the steps to upgrade that ignition to one that will do full timing control. Then you're in business!

Installed the Holley EFI system about 6 weeks ago - the only problem with the system is after I drive the car for say 30 minutes, turn off the engine then about 20 minutes later when I start to drive again it will not idle for a few seconds and I have to feather the throttle pedal to keep it running until it decides to run and idle on its on. Starts and runs great after dead cold starts but refuses to idle after hot starts. Very aggravating. Once it starts to run on its on the performance and response is great ! Any suggestions to remedy the hot starts.

It is really difficult to diagnose something like that remotely but I am always suspicious of timing when this happens. The next time this happens, loosen the distributor and try to adjust the timing just a touch and see if it doesn't start and idle. The longer I work on these systems the more I am finding that timing is at the root of so many problems and it is not where we normally look.

Well, you were right about the timing - we slightly turned the distributor just as you suggested. I drove the car on two separate occasions, one for about 20 mins and the other about 40 mins with the a/c running. After the 20 min drive I waited about 10 mins to restart with NO problems with the idle on the hot start - then the next day from a cold start I drove for 40 mins and waited about 30 mins to restart -NO problems again with the idle on hot start ! My engine is a 383 Stroker Blueprint Crate Motor in a 55 Belair HT 405 hp and 440 torque. I will keep my fingers crossed that it will continue to behave. Thanks for the timing tip.

I'm so glad that worked for you, James--and equally glad you were willing to give it a try! I'm not clairvoyant but I am constantly amazed at how many "fuel injection" problems end up being ignition timing. A lot of folks simply won't even give it a try when I point them toward their ignition because it sounds so preposterous. Good job! :-)

I have a similar problem with restarting my vehicle after it's been driven for a while and gotten up to temperature. If I go into a restaurant or such and try to start 45-60 minutes later, it starts right up then it wants to shut down. AFR is showing 35.4.

If I feather the gas it will stay running but bogs a lot and lots of black smoke from running too rich. It doesn't do this all the time So I never know when it will do it again. Also, my MAP reading is often below 50. Also, I noticed that my installer put the O2 Sensor in horizontal instead of an upward angle if this has anything to do with it.

Whenever I hear that the AFR is pegged at lean and that the engine is running rich I immediately think: Failed O2 Sensor.

I could write a book all of the possibilities here but here's what I'd suggest as the easiest thing to get the car running again. First, re-run your setup wizard just like you did when the Sniper was first installed. Realize that you are going to overwrite any custom changes so you'd need to re-do those after you re-run the wizard. Then, before you start the car, use the handheld to navigate to Tuning > Basic > Clsd Loop Learn > Closed Loop and disable closed loop. If the car starts normally, and if it restarts normally when warm, then you have likely found the problem.

If your EFI system is still under warranty I would approach whomever you purchased it from and see if they won't get you a new sensor. If it is not under warranty you can buy a replacement sensor manufactured for Holley or if you go to a local auto parts store and ask for a Bosch 17025 Wideband O2 Sensor

Recognize that I'm oversimplifying a bit here. You still need to find out what killed the sensor--again, a book could be written on this--and get that fixed. But this should get you moving forward. Good luck!

i'm considering installing a 3x2 set up with Holleys efi 2300 series on my 350 chevy small block. wanting the old skool lot in my 59 El Camino. do you have the complete set up for this procedure? any suggestions will be noted and appreciated.

I think that doing a 3x2 setup with the Sniper 2300 systems would be great! But I should make a few things clear. First, any non-standard EFI setup (this one included) always requires some engineering. Second, the Sniper EFI system is not yet built for dual (much less triple) throttle body setups. That is absolutely on Holley's radar (at least a twin setup) but they have not gotten there yet.

At question is how the Sniper throttle bodies would behave with three individual ECU's sensing conditions and injecting fuel. We do a Twin Terminator Throttle Body Setup rather frequently, but there is only a single ECU and a single set of sensors. But since the ECU is embedded in the Sniper throttle body it's not quite a straight-forward.

I have no doubt that Holley is going to make a twin throttle body setup happen, and I would expect that this has some priority. Once a twin setup is done I think that it will probably be fairly easy to work that into a triple throttle body setup. At this point I'd suggest checking back on our main Sniper EFI System page from time to time. When a dual system comes available you will see it there. Then reach out and ask this question again. :-)

I installed the sniper efi on my 65 mustang and now I cant figure out how to power it , I have 12v dc in switched position from the ignition switch but no during cranking, is there an ALT method.

Your Mustang is going to have some circuits that provide power only when the key is in the RUN position and others that stay on during cranking. It is going to be necessary to find a circuit that stays on both during RUN and START. If you disconnect the low power wire to the starter solenoid you can have someone hold the key in the START position and then probe your fuses until you find those that are powered. Choose from those you find (excluding the starter circuit, which will not be powered in the START position.)

Hi i have a chev 383 stroker engine with a 550-510 sniper efi , it is running well with no problems at all, now i want to fit a supercharger, weiand 144. I dont need the expense of a nother efi upgrade, as i am in tasmania australia and these are very expensive here

I do believe that i should be able to make my existing efi work in this application with the research that i have done so far. I think that i need to fit another map sensor to the manifold instead of using the throttle body mounted one. If i am right in thinking this can you please tell me which map sensor i need and how to wire it into the sniper efi system or can i buy the correct one that can simply be plugged into the existing wiring harness of the 550-510 sniper, obviously i will need to do fuel remapping etc which is no problem, would like to be able to make this work . Your help is appreciated

You are right on target as far as understanding that you need an external MAP sensor in order to make this work. Unfortunately, there really isn't a straight-forward way to accomplish this with the standard Sniper EFI System (though that all changes with the Super Sniper.)

At issue is the fact that, because the ECU is internal to the throttle body system, there is no practical way to "intercept" the signal and splice in a signal from another MAP sensor. Nor is there provision for an external sensor. And with a draw-through Supercharger application, that means the ECU won't see the actual manifold pressure, and it just won't work.

External sensor capability is fully half of what the Super Sniper brings to the party. That extra 8-pin connector provides sensor ground, voltage, and inputs for up to 3 custom sensors. In addition to making these connections to the new external sensor, all one must do is plug the port to the internal sensor and follow the instructions that I've provided on the Holley 3.5 Bar MAP Sensor product page. Voila, you've got your external sensor providing manifold pressure to the ECU.

Of course, none of this helps you in your quest to install a supercharger on your standard Sniper. And since we do ship so many systems to customers in locations like Australia and New Zealand I can certainly sympathize with your situation. But I think that if you are destined to go this route then you would be best off to repurpose that standard Sniper and go with a Super Sniper.

Why does my sniper (even when hot) idle up above the set of 900 rpm for at least 3 seconds and then idle back down to the set idle rpm? It is a 383 stroker motor in my 67 Chevelle.

That's precisely how the system is designed and the intent is to ensure that the engine starts strongly without stalling before settling to an idle. This behavior is controlled by the IAC Parked Position and the Startup IAC Position Hold and Decay Time in the Idle configuration. You can change them from the defaults but I generally recommend not changing them too much. Using them handheld you navigate to Tuning > Advanced, > Advanced Idle > IAC Startup and you will find the numbers there. In the software you will see the IAC configuration setting (the tachometer icon) and modify the settings in IAC Settings and IAC Parked.

I have a question for you that would benefit everyone who will be running a turbo with their Super Sniper EFI. The Holley manual does not tell you where to run the line (hose) from the external bypass regulator's boost reference port. The injector spray ring seems to be more under the throttle plates, which would usually dictate that the injectors would be exposed to manifold vacuum, and therefore would need the boost port on the regulator to be plumbed under the throttle plates.

Most blow through carb guys would plumb the regulator boost port into the carb hat. Based on your knowledge and expertise, where do you recommend plumbing the boost reference port? In the hat, or in the manifold? Is the Sniper smart enough to allow for either, if say, you are running the system on a 207 cubic inch V6 that may require a lower fuel pressure at idle so the set lower limit of pulse width would allow a proper AFR by using manifold vacuum as the source for the regulator boost port?

The purpose of the boost (or manifold pressure) reference port on the regulator is to ensure that the pressure of the fuel line relative to the pressure at the outlet of the injector is fixed. Without that boost reference the ECU will direct the injector to stay open too long when the injector is spraying into a vacuum, or too short when the injector is spraying into pressure.

In the case of the Sniper EFI System, the annular discharge rings on the Sniper EFI System are above the throttle plates. So manifold pressure referencing is irrelevant on a naturally aspirated or draw-through supercharged engine, since the injector will never see vacuum.

But if you are doing a blow-through application, you sure better account for the pressure that the injector is going to be spraying into. And the way to do that is to connect the hose for the boost pressure reference somewhere above the throttle plates, most likely in the hat (as you suggest.) This way, if you are pushing 10 PSI there at the injectors above the throttle plate then the fuel pressure will be increased from the normal 60 PSI to 70 PSI. But since it is spraying 70 PSI into 10 PSI over atmospheric pressure, the actual flow of fuel will be the same as if it were spraying 60 PSI into atmospheric pressure--which is precisely what the Sniper ECU has calculated.

While it is true that the throttle plates pass over the annular discharge rings as they open, at that point they are open enough that the pressure above the centerline of the throttle plates is the right one for the your boost reference.

I do not recommend trying to adjust the fuel flow with fuel pressure. That should never be necessary. Even with a smaller engine such as you suggest, the amount of fuel specified in the base fuel map is injected based on the pulse width calculated using the fuel pressure. If you need less fuel, don't turn down the pressure. Adjust the fuel map. :-)

I have the sniper unit wht heat rang plug should i run for a stock 350 chevy with auto an what should timing be. running a AC R43 right now should i go hotter.

It is really not possible to accurate answer this question without a lot more information. My recommendation remains the same in all cases: Start with precisely the spark plug and timing recommended by the manufacturer for that engine. The direction you go from there must be guided by your own read of the plugs as well as what you hear and feel in the engine. EFI systems are not and never will provide a substitute for good engine tuning techniques. Instead, it provides you with a new set of tools for doing what technicians have been doing for 100 years.

Considering buying a Holley Sniper EFI system and Holley distributor. I have a 69 Camaro with a 350 V8 which has an Edelbrock 4 bbl. carb and a mild performance camshaft. I am also planning to get the Holley distributor and Sniper fuel tank. Is the stock GM Powerglide transmission compatible with this set up?

Yes, the combination of the Sniper EFI System, Holley HyperSpark distributor, and the Sniper Fuel Tank System would be a great combination for your '69 Camaro. You might consider opting for the Holley OE-style Tank Module instead of the complete EFI Fuel Tank System if your existing tank is in good shape. These are easy to install, work wonderfully and are a good bit less expensive than the complete tank (especially when you factor in the cost of installation components.)

I am installing a 550-511K on a Ford 460 that has a DUI distributor. I don't see anywhere in the instructions where this can be set up with timing control with the DUI. Am I missing something here?

I never say never when it comes to ignition setups. But trying to make this work with a DUI is not a route that either Holley or I recommend. Take a look at the Sniper Ignition Timing Control methods that are recommended and my tips for implementing them.

I am installing a sniper system on a 68 to with a well built 400 engine and i need your advice. customer wants a 200 horse nitrous shot, which the engine will definately handle. what is the best plate system to run with the sniper, and which distributor should i run for timing control with the (wet) nitrous system? your help is greatly appreciated. i will definately be purchasing the necessary parts from EFISystemPro

The selection of the nitrous system is probably not as mysterious as you might think. You can go with any 4150-style plate system that will support the HP levels you are trying to make. I am not aware of a dry nitrous system that lets you save money by leaving out the fueling solenoid and other components so just buy one that has that and you can leave those components out if you intend to do dry nitrous.

At the horsepower levels you suggest you will definitely need to opt for the eight-injector Super Sniper. The four-injector Sniper is rated to handle up to 650 HP but not if 200 of those HP are made from Nitrous, which requires a higher brake-specific fuel consumption. And, as always, if a HyperSpark distributor is available for a Sniper-equipped engine that is always the right choice, followed by a Dual-Sync. This Article will give options for those not so fortunate.

Holley sniper with hyperspark on a 302 with a e303 cam. Any idea what a good starting point would be for a spark plug gap? I’m currently set up at a .54 ish gap

I don't claim to be a guru on spark plug gap but I always start with the exact plug and gap specified for a specific engine. Then, if you've upgraded the coil you can open the gap a bit and watch how it responds. In general, you need LESS spark gap with EFI because the fuel atomization is usually better. And as the system learns you'll find that only gets better.

Sorry, another question from an individual who did not purchase their system ... found your website post purchase unfortunately. My question is: upgrading a Chrysler factory electronic ignition to an MSD ready to run #8386 distributor, what ignition type criteria do you enter into the Sniper set up wizard? Coil, magnetic, cdi?Looking for some clarity on this issue.Thanks,Ian W.

You can solve that with a voltmeter. If the coil is powered with 12 volts then you're safe to use the yellow wire and the negative side of the coil (Coil -) to provide the tach signal to the Sniper.

Leave a Comment