In my experience the far majority of Sniper EFI customers never have a problem with radio frequency / electro-magnetic interference (RFI/EMI). However, a small percentage (about 10%) runs into this challenging gremlin. And when you do it can seem like nothing is working right. I offer this troubleshooting guide to give you some of the symptoms of RF interference, common targets and sources, and then tips for solving it.

The first response I typically see to telling someone they have RFI/EMI issues is denial. That is understandable, because there may be absolutely no other indication. But denying the problem won't get it solved. And finding the problem often is easier than you might think.

As A Minimum, Do This

Whever someone has an RFI problem they always start by explaining the effort they have made to separate their wires from each other. Surprisingly, I've almost never found that to be the problem. Not because it can't be--rather, because most installers recognize that running a spark plug wire and a signal wire side-by-side and/or in close proximity is begging for problems. So if you recognize that then you are probably okay in that area.

Instead, if you are experiencing RFI then do yourself a favor and do a complete ignition tune-up: Spark Plugs (the exact plug specified by the manufacturer for your engine), spark plug wires, cap, and rotor. To start, gap your plugs at the gap specified by your engine manufacturer. Why? Increased gaps increase spark resistance, causing energy to be emitted from the plug wires. Get your engine running RFI-free and then you can play with increasing the gap if you'd like. Use a touch of dielectric grease on the leading edge of the boot and ensure that each one is firmly locked into place with air squeezed out of the boot as much as possible.

Here is where the denial starts. "But you don't understand, My spark plug wires are brand XYZ, the best on the planet, and for that matter they are brand new!" Invariably, this is the user that, after weeks of frustration, replaces the wires on out of sheer frustration and finds that it solves the problem. Even new wires occasionally have defects, and all it takes is one crack in the insulation for a wire to start arcing to the nearest grounded chunk of metal.

Some wires simply won't work in an EFI-controlled vehicle. And, surprisingly, not just any wire that says "eliminates radio frequency interference" actually does. Personally, I have had the best experience with Magnecor wires. We used to sell thousands of dollars of these spark plug wires a year until I found them too difficult to deal with. But the quality of their wire is unsurpassed. You'll simply have to buy them direct if you're interested. Just don't trust their application guide--be sure to specify the length of each wire in your set. Then you'll get an outstanding product. When you install them, it's a good idea to put a bit of dielectric grease on the inside of the boot on both ends of the plug wire as well. Update: MSD's Super Conductor wires are lower resistance than I like to see but I'm not hearing of anyone who has has RFI problems after installing a new set of those. Because they are easier to purchase than the Magnecor my favor is leaning in their direction.

When you are inspecting/installing your cap and rotor, pay particular attention to the tab on top of the rotor and the button in the center of the cap. If that gets out of alignment you will have a fireworks show going on under the cap and never even know it. Also pay attention to the contact surfaces of the rotor and the cap. If these are sooted up then you might have found part of your problem. Use a clean white cloth and wipe inside of the cap. If you pick up soot then you've got arcing, and that's not good.

If your distributor is old then recognize that it could be rotating in a non-concentric manner. That will also create arcing. You will ether need to have it rebuilt or replaced.

Now, read on to get a deeper understanding of the problem.

Symptoms of RF Interference in Sniper ECU's

The first thing to realize is that RF interference can manifest itself in ways that will have you suspecting and replacing everything in the system.

If you datalog the Sniper ECU and see multiple overlapping traces for the same signal, you likely have RF-induced problems. At low levels RF interference will often reset the ECU so quickly that the engine will not stall.

If you think your throttle position sensor is failing, working some of the time and other times it is registering negative percent, my first suspicion: RF Interference. Not that your TPS can't fail. But the failure tends to be deterministic, not random. And just as it stalls you look down and see a TPS reading of -22%, that's a pretty good clue.

And finally, if your engine is stalling completely at random and nothing else really makes sense, then you might have RF interference issues.

Quick Checks

Ignition Wire Lightning

There are a couple of things that you can do that are relatively easy and might give you some solid leads on the problem. One is to get the vehicle somewhere it is as close to pitch dark as possible. Crank the engine and peak under the hood. One of our customers did this and said he saw what looked like a lightning storm. This despite having a quality brand of plug and coil wires that were well-routed. The problem is that even the best wires don't last forever and all it takes is a crack in the insulation at a key point to create arcing. That arcing will result in EMI. If you don't see any lightning under the hood, you might use a wooden dowel to move the spark plug and coil wires around just to be sure the problem isn't a dynamic one with the motion of the vehicle or underhood air currents..

Alternator Issues

I have updated this post a couple of times and each time it seems I point a more suspicious finger at the alternator. And if you think about it, it makes sense. Most Sniper EFI Systems are installed on much older vehicles, many with much older alternators. When we say, "They just don't make them like they used to", we generally mean something is not as good as it used to be. That is not true of alternators.

You may know that old-school alternators (such as the Ford 1G, 2G/GM 10SI, 12SI, etc) do not support high current draw at idle. Newer alternators, (such as the Ford 3G, 4G/GM CS130, CS144), are able to produce near-full current at idle speeds plus they are so much more electrically quiet. (Thank you Danny Cabral for pointing this out so well on the Holley user forums.)

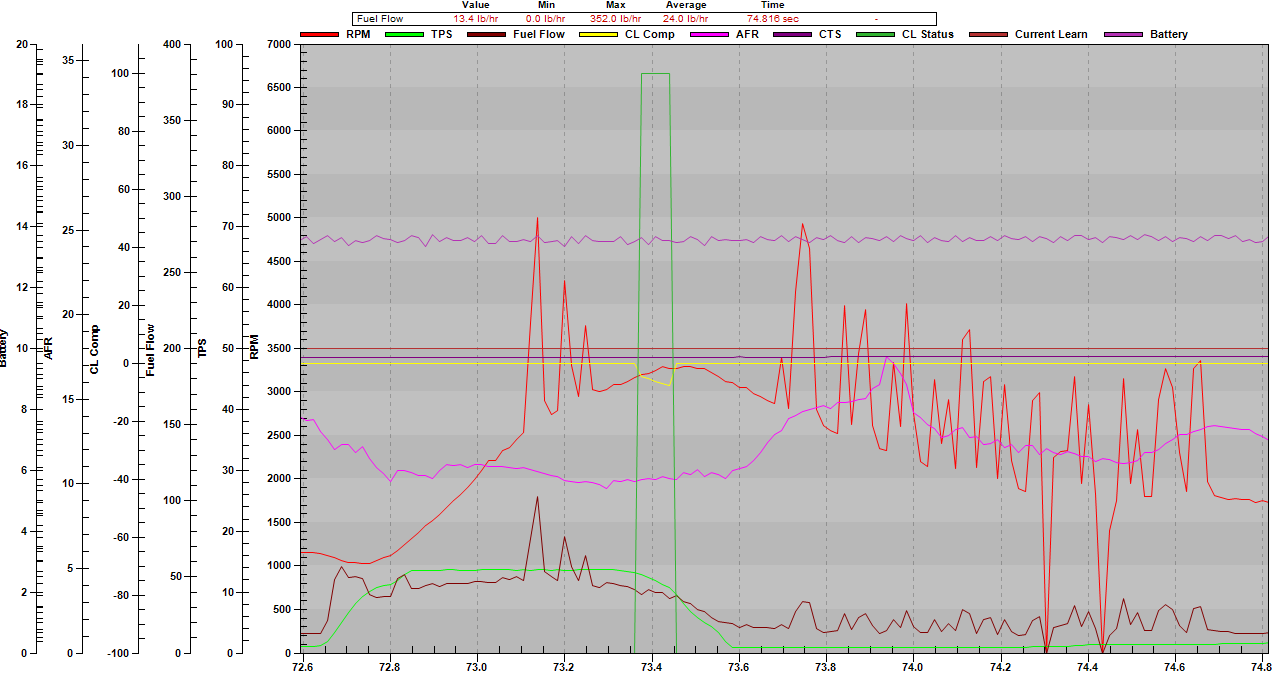

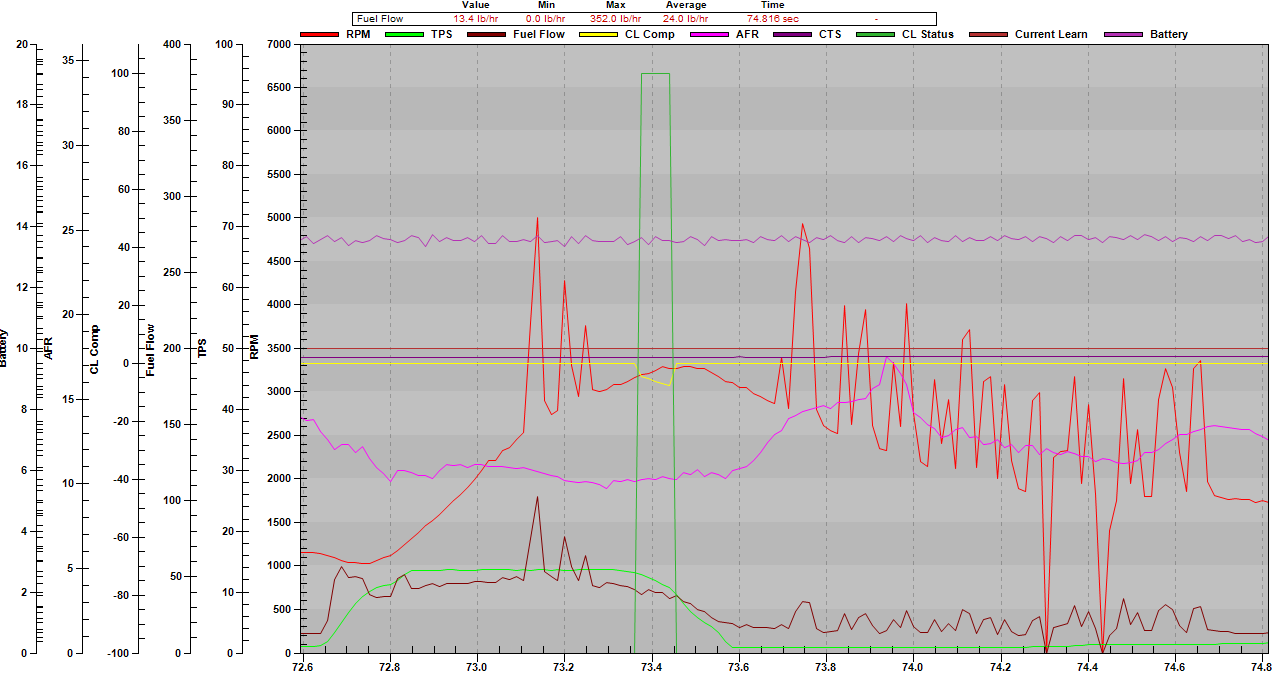

So, a second quick check is to disable the alternator (preferrably by removing the belt). It is simply amazing how much EMI an alternator can produce. Doubt it? In this first picture you see a quick blip of the throttle (light green trace) and the resulting increase in RPM. And you can plainly see the interference riding on the RPM signal. But you aren't the only one seeing that. See the spikes on the brown fuel trace? That's because the ECU was seeing the same thing and flooding the engine because of the false RPM readings.

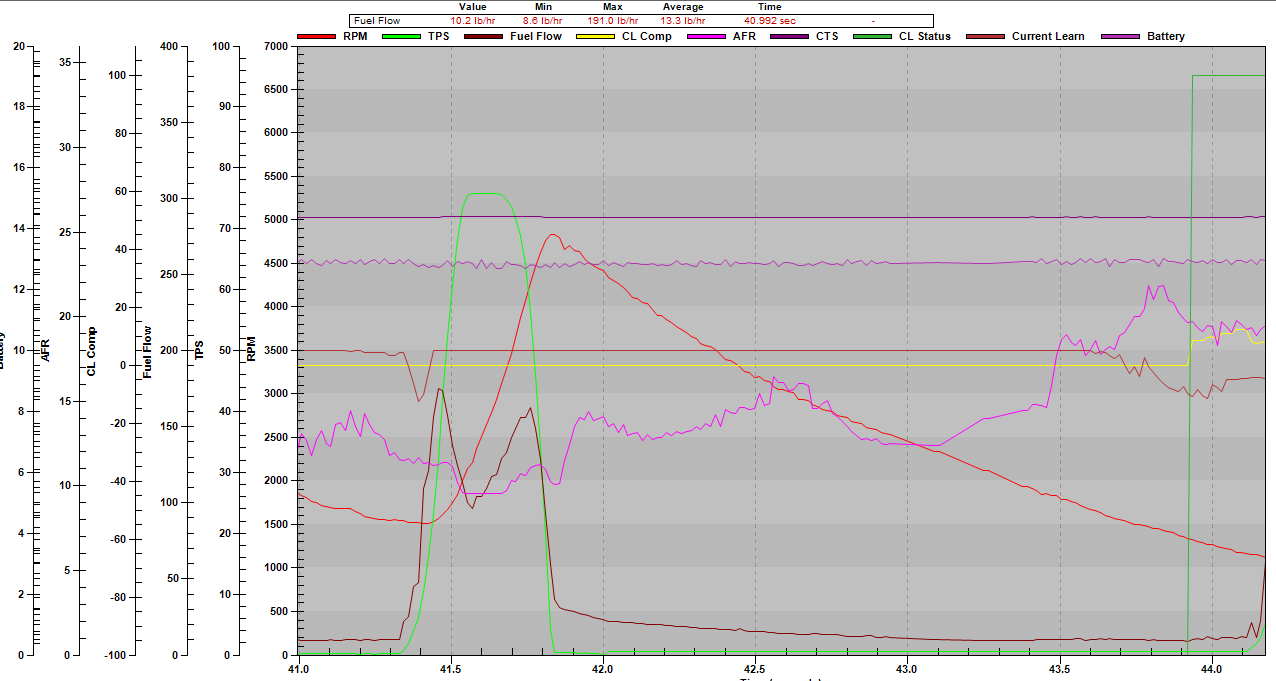

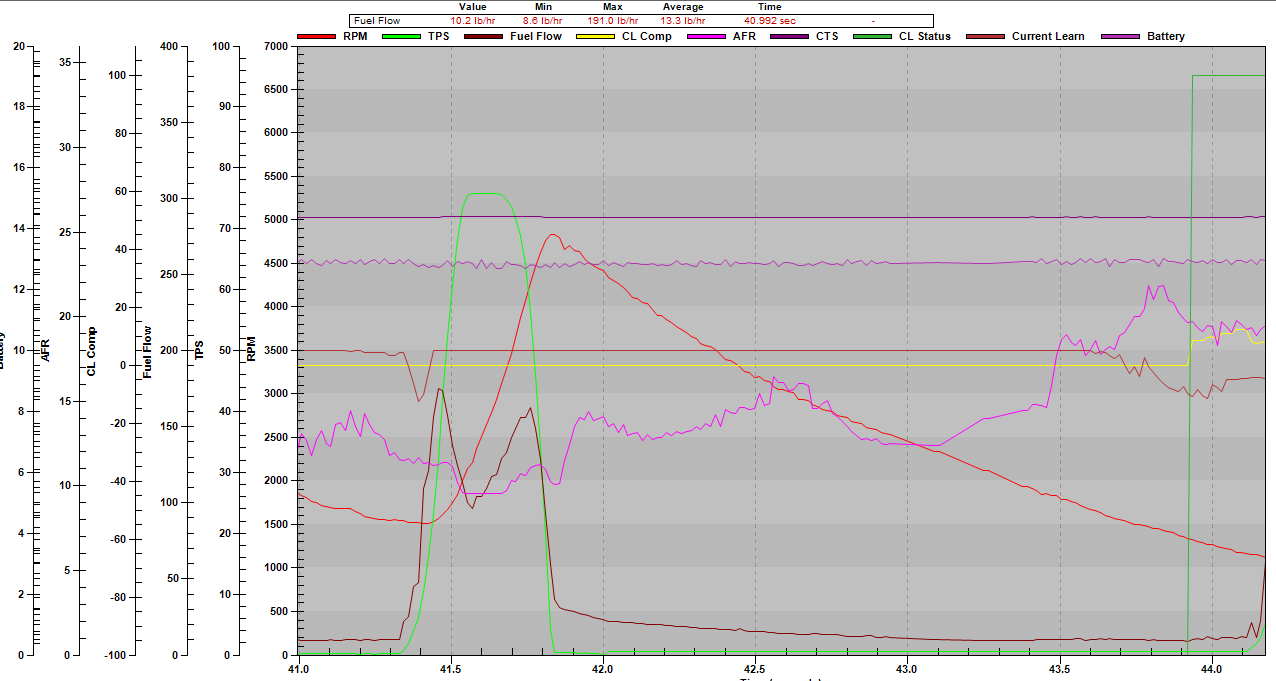

I mentioned to the customer that he could be getting EMI from his alternator and he thought, "I know a quick way to check that--disconnect the alternator!" So he did. The immediate result is shown in the trace below. Start by removing and cleaning every single power and ground connection between the alternator and battery. If that doesn't work its probably time to replace that alternator.

Susceptible Targets of RF Energy

Before launching into the source of RF energy, it may be helpful to recognize those components of the Sniper EFI System that are most susceptible to RF energy. Normally, powered sensors are not bothered by RF impulses. These sensors (which includes the coolant temperature and MAP sensors) receive a 5-volt source and ground.

Low-Powered Signals

On the other hand, low-powered signals (like the Wideband O2 sensor), signals that generate their own power (like the magnetic pickup in a distributor), and resistance-based sensors (like the Throttle Position Sensor) can be terribly corrupted by RF energy. In fact, the magnetic pickup is so susceptible that I recommend using a hall effect sensor (such as in the Holley HyperSpark Distributor) when practical. In fact, if you have concluded that you don't need ECU-controlled ignition timing but can't resolve your RFI problems through the other means discussed here then I'd say it is imperative that you consider switching to the HyperSpark distributor if one is available.

Magnetic Pickups

In the case of the magnetic pickup (more accurately referred to as a varible reluctor or VR), this susceptibility is compounded by the fact that many do not recognize that the sensor must be tuned to the environment. We will discuss tuning tips a bit later in this article. For those who want to understand VR sensors in a bit more detail, this is an excellent article.

Spare Wires

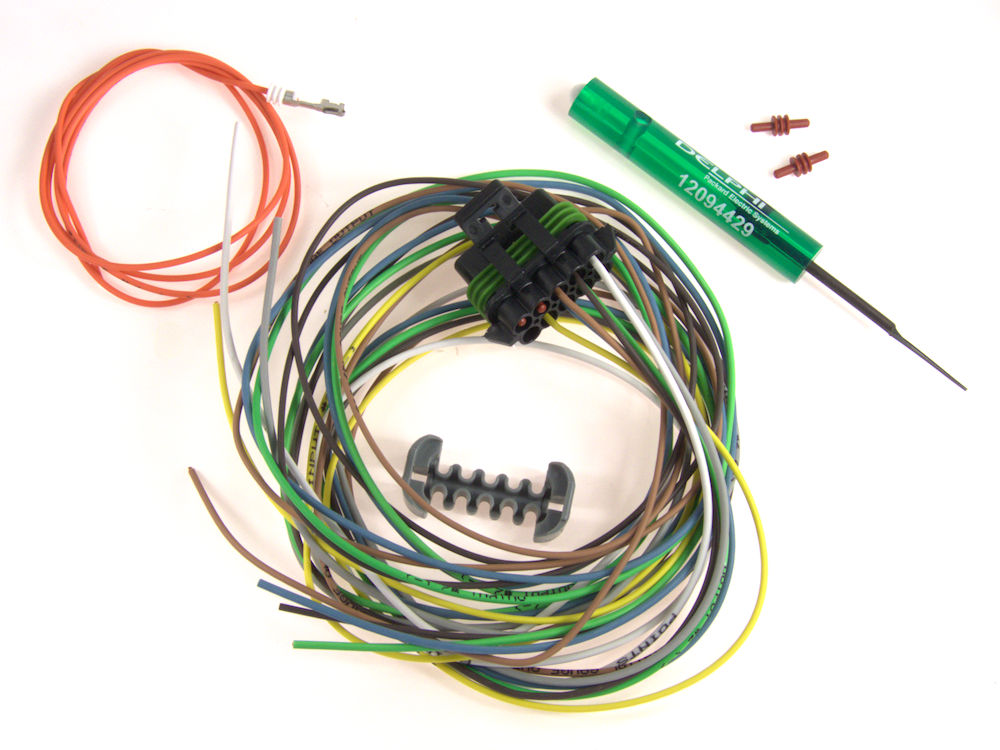

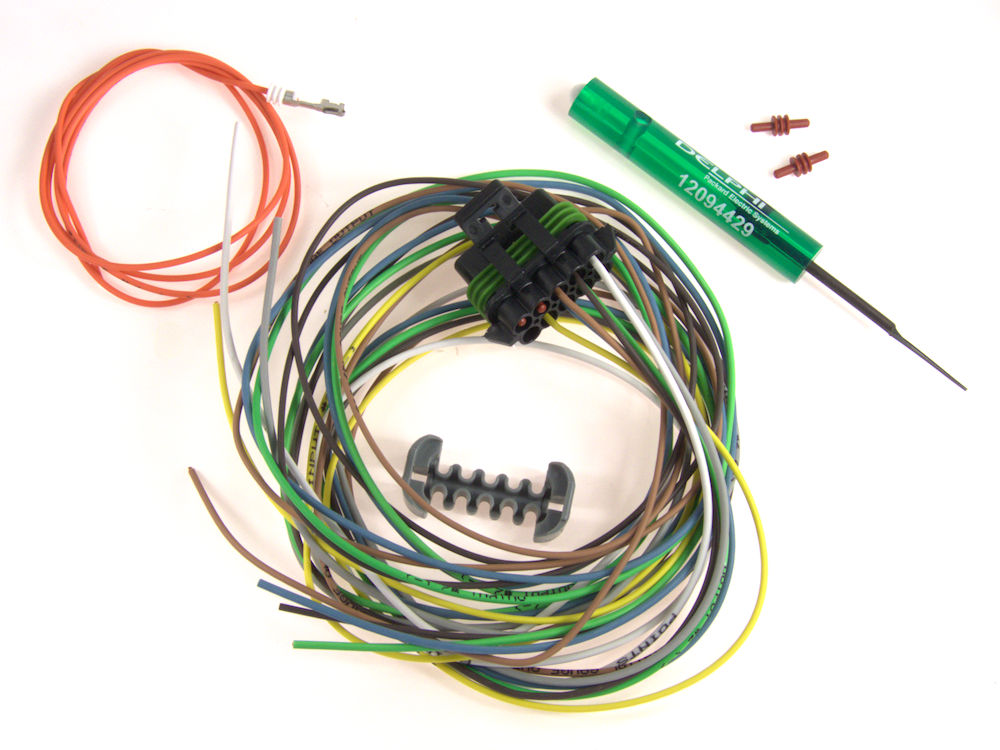

Another thing that every installer should do is remove all wires that aren't being used. In your 7-pin harness, you will be either using the yellow or the purple wire for RPM input. In the 10-pin harness, the white wire will only be used if you are doing ignition timing control. Super Sniper or Sniper XFlow? More wires that are potentially unneeded. These wires should be removed at the connector and replaced with a sealing cavity plug. We offer a spare wire removal kit for just this purpose.

Bundled Wires

With the advent of EFI systems like the Sniper EFI System more and more of the details formerly left to the installer are being completed at the factory to provide a "plug and play" experience. That's generally a good thing. But since the factory can't know how long wires you might need they tend to make them too long. In some cases, way too long. These often end up bundled up in the engine compartment.

These wires are necessary so they can't be removed like the spare wires mentioned above. But most of them can easily be shortened to a length that dramatically decreases their susceptibility to RFI. Yes, doing this means that you will need to cut wire from a fully terminated harness. But if you're fighting RFI then it's time to step up and do this.

A great example of a wire that's way too long is the crank trigger pickup on the Sniper EFI System. You've got two options: re-terminate or cut-and-splice. The pin removal tool mentioned in the section above can be used to remove these pins from the 7-pin connector on the Sniper main harness. This Crimping Tool is available with the Delphi 12048074 Metri Pack 150 Series Female Terminals that you'll need to reterminate after you shorten the wires. Alternatively, you can cut a section out of the middle, strip/solder/heat-shrink the pair down to a reasonable length. Other EFI Systems may require different terminals.

Note: Do not attenpt to shorten (or lengthen, for that matter) an O2 sensor's pigtail. It is internally shielded and can easily be rendered an expensive failure.

Interference from Typical RF Sources

All engine compartments have a bounty of sources for RF noise. The most typical culprits are the spark plug and coil wires. The first thing you should do when you suspect that you have RF interference is to double-down on all of the best practices that are given in the installation manual regarding wiring.

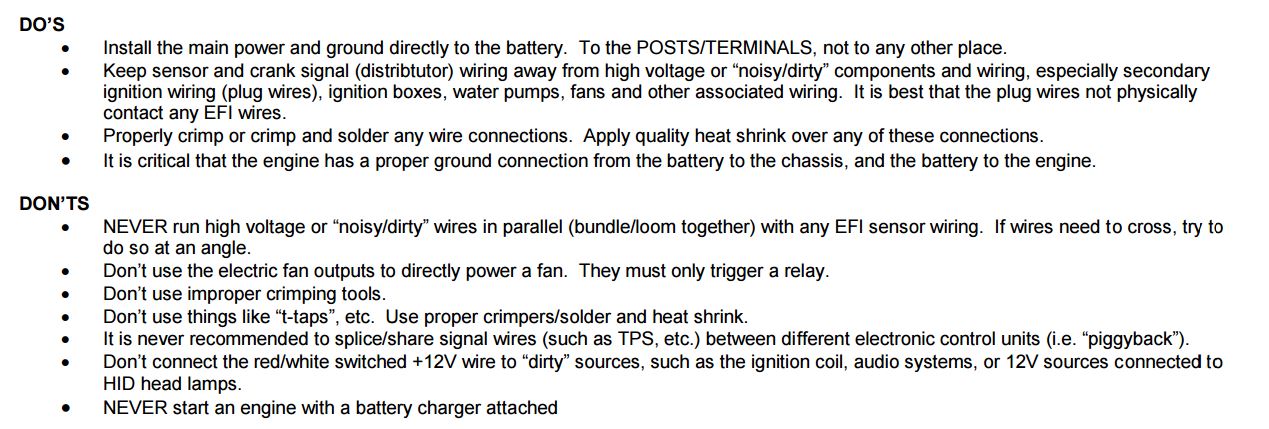

In the installation manual you will find a "General Wiring Reference" with two paragraphs of "Do's" and "Don’ts". Do the do's, don't do the don'ts--it is that simple. If you have violated any of these then don't bother reading ahead until you have fixed them. (Yes, connect the power and ground directly to the battery!)

Once you have done this, make sure that all of the signal wires (especially those on the 7-pin and WBO2 harness) are as far from the spark plug wires and coil wire as possible. Where you do pass these high-voltage wires ensure that the wires are running at 90 degree crossing angles--never run in parallel.

The above paragraph is even more important for the WBO2 harness and the Crank Signal or Coil (-) input (depending on which you are using for RPM signal input.) Ensure the Crank Signal Positive / Negative wires (Purple and Green) are twisted snugly together the entire length of their run.

Interference from Atypical RF Sources

If you have done the steps above then you likely will never have any problem with RF interference. But, if your symptoms persist then you need to consider that you may have an atypical RF source.

Recently I received a data log from a customer who said that his car starting misbehaving when it got warm. I look at the data log and noted that every time the engine got to 184 degrees it lit up with RFI. "Hey, you don't happen to have an electric fan coming on at about 185 degrees, do you?" Turns out he did. Dug down, cleaned up a bad ground, problem solved.

This fan is an atypical source of RFI. Atypical RF sources can be even stronger and have more deterministic effect on the ECU than the typical ones. In one case I saw an installation where the large, oval air cleaner overlapped the distributor. The car generally ran well without the air cleaner but the moment the air cleaner was lowered to the top of the throttle body, BAM, it shut off like you'd hit the key. 100% of the time and without variation.

Reflected RFI situations like this one requires more in-depth investigation.

Interference from Coils

Ignition coils can begin to break down internally, doing so gradually so that the engine will still run (particularly at idle.) But inside they are a cauldron of RF energy that is being broadcast all over the engine compartment.

Unfortunately, I cannot offer you an easy litmus test that shows if the coil is breaking down. If you had precise electrical measuring equipment it could be done but that is far beyond what almost anyone has. So, failing that, replacing the coil is a good way to test this theory. I have been told that e-core coils tend to emit less RF energy than standard canister coils and I believe that to be true.

Interference from Rotor Phasing Issues

This last section is only for those who are doing ECU-controlled ignition timing with their Sniper ECU. Doing this requires that the rotor be custom-phased so that it is in close proximity to the corresponding spark plug tower at the timing advance position where the spark is triggered by the ECU.

In a non-ECU controlled ignition setup, such phasing is done automatically. The mechanical and vacuum advance mechanisms within the distributor physically advance the spinning rotor so that it is in precise position to deliver the spark at the desired advance.

ECU-controlled timing would conflict with these mechanical advances, so they are locked out (in the case of the MSD distributor) or are non-existent (in the case of the Holley Dual-Sync and HyperSpark Distributors.) The rotor must be pre-set (phased) so that the rotor and tower are close enough transmit the spark energy without creating a long arc. If that phasing is not precisely correct then this long arc is the source of a huge emission of RF energy. Bad things will happen regardless of how good of a job you've done grounding and routing wires.

What About Shielding?

Shielding is really taking the wrong approach. Instead of fixing the problem, we leave the problem in place and go on the defense, trying to cover up wires, ECUs, and sensors that might be affected by RF energy. However, if you have done everything else then this is absolutely worth a try.

If you're going to try this, start by wrapping the harnesses wherever they are exposed. Here are some of the materials that one of our customers used with some success:

Sniper Tuning Tips for Magnetic Crank Pickup Users

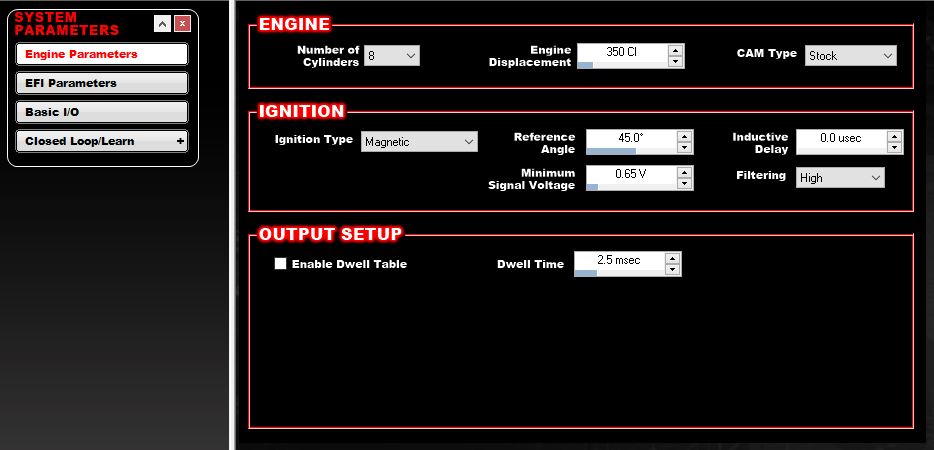

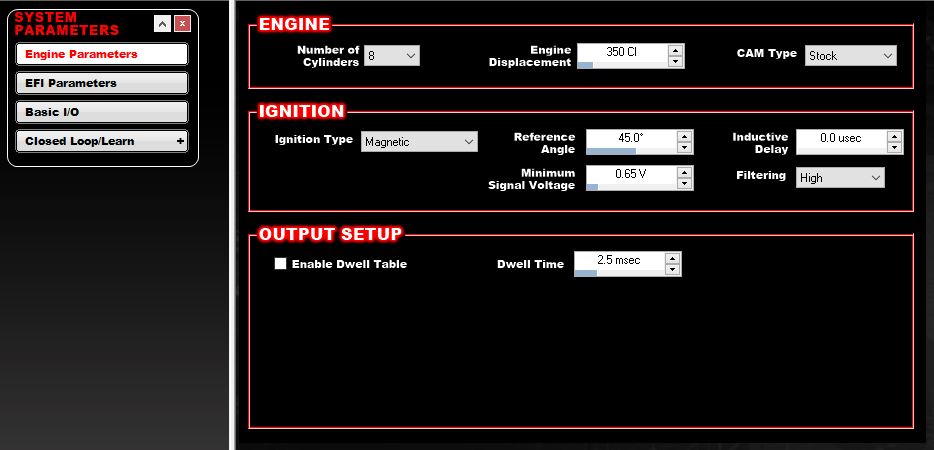

If you are using the magnetic pickup from your distributor to trigger your Sniper, there is one very important step to take. It is best practice is to increase the Minimum Signal Value (which is currently defaulting to 0.0v) up to at least 0.35v and maybe as high as 0.65 volts.

Unfortunately, it is not currently possible to change the MSV from the handheld. To do this will require downloading the Holley Sniper Software. Under "System Parameters" is a section called "Engine Parameters" and a section called, "Ignition". If you have "Magnetic" selected as your ignition type then you will see a place to set the MSV. If you don't have "Magnetic" selected as you rignition type then none of this applies to you.

If your MSV is set to 0.0v it means that any amount of voltage that is able to induce itself onto the green/purple wire pair will be interpreted as a pulse. Don't get crazy--if you set this too high then you will have troubles cranking the engine. I recommend setting this to 0.35v initially and then increasing to 0.5 and then 0.65 if that does not resolve your RF problems.

Note also that there is a "Filtering" selection that can be toggled between "Low" and "High". Changing that may have some benefit as well.

Conclusion

RF Interference is an unavoidable enemy to successful EFI operation so it must be carefully and thoughtfully managed. The best practice is to take these management practices into consideration during the installation process, before RFI becomes a problem. However, in the event that RFI has reared it's ugly head in your installation, these tips should put you on the right track.

Click here to read more articles from Chris about the Sniper EFI System!

Sniper EFI+

Sniper EFI+

Terminator X TBI+

Terminator X TBI+

Terminator X MPFI+

Terminator X MPFI+

HP-Dominator EFI+

HP-Dominator EFI+

EFI Components

EFI Components

18 Comment(s)

Very good read! Great tips and advise. Many, many years ago I discovered the "lightning storm" mentioned in the article. I discovered it back in the mid 1980s. I've used this method for diagnosing misfires ever since!

I'm glad you enjoyed the article. Thanks for commenting!

Just want to take a moment to thank Chris for all of the assistance during the timing control set-up of my Sniper installation. I had a little trouble getting a signal to my MSD box to fire the coil during cranking. He directed me to a few articles and I'm just about done with the set-up after getting what was most likely RF Interference issues sorted out. Note that I have only purchased a CAN bus cable from Chis, yet he took the time to help me learn. This is where I will get all of my EFI equipment from now on.The MSV and filtering settings make a HUGE difference. Changing those two parameters took my car from a no start condition to idling well and ready for final tweaks.

Glad I was able to help! :-D

As much as I hate to admit it I myself was in RF signal denial. On a new-build I swapped over to the EFI sniper and dual sync distributor on a 383 big block Mopar with 810 Mi break in. I swapped from a Edelbrock 750 and a Carter mechanical pump. This install is on a 2000 Ram 1500 2 door short bed full size truck. Many times I called Holley and ask why it wouldn't tune itself. They told me I had RF problems that I failed to accept.

I finally found this piece that Chris produced, read it, thoroughly went back and took the time and trouble to check on all new equipment--plugs, wires, boots, wire routing and all. I found my problem. Today my truck started fine, ran great, and is now learning. I am so thankful to have found this article on RF signal denial. I was truly in denial. The best advice I could give is don't be in denial. Listen to what the technicians tell you. Sometimes it's as simple as just changing a boot on a plug wire.

Great things are achieved through persistence. Nice job!

Should I change my non restistor style spark plug to a resistor type. My only issue as present is some misfiring popping through the throttle body. Minor but has only just started after 3 weeks . Cleaned all the plugs and it seemed fine. But i did notice they are non restistor style ngk b6es. I have a 1970 el camino with a 350 sbc msd 6al and blaster coil with msd leads. Any advice on the plugs will be awesome.

Here is my advice and I follow it strictly in my own installations. Start with the factory-recommended spark plug. Where there are several options, opt for a conventional copper plug. In the case of our Project Shop Truck with cast iron Vortec heads, GM recommends the ACDelco R44LTS6 gapped at 0.060 inches.

On the point of gap I'm going to rebel a bit for the initial start-up. I"m going to gap down to 0.35 to 0.45. Provided I don't find any RFI then I'll increase the gap and make sure I don't have any problems. But the primary goal has to be the prevention of RFI. At that point, if I do anything that creates RFI then its an easy matter to back up.

A final word on plugs not related to RFI. When you're installing the Sniper, and until you have it running well, stick with copper and swap to a new set at the first hint of fouling. They are a couple of bucks each, right? Buy two or three sets. You can take them back if you don't use them. But if you have any problem (particularly with a rich running condition) you can know that you know that it's not spark plugs when you can just swap in a fresh set.

Would having a hole drilled in my Cap for phasing be bad for emi/rfi ?

I sincerely doubt that. There is nothing that I am aware of in the material of the cap that restricts RFI/EMI in any way. That being the case, RFI/EMI will pass through the cap itself whether it has a hole in it or not.

I'd like to echo Zachary P's comment above! I had my system installed by a local performance shop so I don't know where they picked up my master kit. I've got a huge bucket list trip coming up to the NCM in Bowling Green end of the month and I had some issues this past weekend. I tried Holley but didn't get much, so I thought I'd try Chris but knowing he owed me nothing.

Well let me say he responded to my questions and concerns quickly, read some of my datalogs and provided some great advice. If nothing else Chris' enthusiasm and confidence in the EFI products quickly gave me peace of mind. I'm still on schedule to cruise my '71 Stingray from Ottawa, Canada to what should be a blast of a Corvette party at the NCM. (National Corvette Museum for those who are wondering).

Would I recommend Chris and EFISYSTEMPRO? You betcha, and I did last night at a cruise in with a fellow Stingray owner who's got an EFI upgrade on his wishlist! Keep up the great work Chris, I'm sold!

Thanks so much for the positive comments. Just knowing that I'm helping folks is very rewarding!

what fixed the air cleaner issue. ive done dozens of these things and have one where air cleaner goes down bam she dies.

I believe that thinking of this as the "air cleaner issue" is what makes this problem a bit misleading. Strictly speaking, it's an RFI issue. It just doesn't happen to conentrate enough RFI to create the instant ECU-stopping effects you see until the air cleaner is in place. As always, the identification and elimination of the source of the RFI is where one's attention must lie--not doing things like shielding ECUs and grounding air cleaner bases and those sorts of things.I believe the solution lies in creating wiring "zones". One zone where there is nothing but ignition wires and another zone for power and signal wires. For example, on our shop truck our spark plug wires go immediately down and straight under the manifold to the spark plugs. The coil is similarly mounted to put the coil wire in this zone. The wiring from the Sniper and HyperSpark go up and away from the distributor.We hope to write a more detailed article on this soon. Stay tuned!

Terminator X Max 700R4 LS2 L92 heads and LS3 525hp cam and Jim Inglese 8 stack fuel injection. Cold starts good, hot starts good and runs good in open loop. Getting what I think is false lean readings. The AFR trace on all my data logs since February have looked the same, new install. Have tuner now still runs very rich, have to run open loop to get home, runs pretty good. Been through seven 02 sensors and seven or eight sets of plugs. AFR trace has 2 point lean spikes. 14.7 target AFR jumps to 16.4+. No exhaust or vacuum leaks. Do you think it could be RF Interference. I don't know much about tuning but I'm getting frustrated, nobody has and ideas. Tony from the Holley forum thinks it might be the ECU.Thanks for any help

I agree with Tony. The O2 sensor is not a passive sensor that simply sends back data. It must be actively driven and controlled by the ECU. I have seen cases where the ECU gains an appetite for eating O2 sensors. Very rare but when that happens you need to stop feeding it O2 sensors at maybe number 3 or 4 (not number 7) and send the unit back to be checked.

I bought a new holley sniper , dual sync dist., coil, and holley in tank fuel pump, When engine got hot it would go crazy. RPM going up and down , miss firing and backfiring. Found out that it was due to rfi/emi. Removed all the unused wires from harness and wrapped all the remaining wires and harness with rfi shielding tape. Car runs perfect now!!!!!

Great job, Dewayne. You're proof that it can be done. It just takes diligence.

This is by far the best guide to EMI/RFI sources and troubleshooting I’ve come across on the web. Thank you Chris.

I’m currently fighting such a problem and it’s really frustrating. I used the tip of checking for arcing in the dark and bingo … I can see white light between the epoxy-sealed body and metal casing on my MSD HVC Blaster coil. I’m guessing this isn’t normal and could be the primary cause of my problem? Is this the coil failing or could it be a sign of a downstream issue (with the plug gaps maybe) that’s backing up too much resistance in the coil? Even if there’s a downstream problem which needs fixing, sure the coil shouldn’t be arcing from what appears to be from the side of its body? Any ideas?

Well, first off, you are perceptive in noting that anything that increases resistance on the the plugs can lead to spark energy going where you do not intend for it to go. That's why I am not a big fan of increasing spark gap.

But the in-coil arcing you are experiencing doesn't sound right to me either. I would absolutely recommend replacing that. Good find!

Hi Chris, I recently had a sniper system installed on my 55 nomad with gm zz4 350. I did the Holley distributor as well. It suffers from rfi. I’ve been able to find some arching. In the dark I see spark from the nut on the spark plugs running to the head bolts. It appears to be on most of the plugs. I’m running msd street fire wire set. Any advice is greatly appreciated Cheers

First, one must address why ignition charge is preferring to run down the side of the spark plug rather than arcing across the gap. Normally this means you have too much gap. The Internet know-it-alls will tell you to open the gap up to get more power. Generally, that is bad advice. Gap the plugs to the manufacturer-recommended gap and if you are running big compression or boost you will have to either increase your ignition power or CLOSE the gap to compensate. And just because you increase your ignition power that doesn't mean open the gap. Lest you run into what you are finding.

Next is to replace the spark plugs. Once arcing occurs, carbon traces form on the outside of the plug and that provides an even better conduit for ignition energy. And before you put the plug wires back on, inspect the boots very carefully. If they are not completely limber inside (and they may not be if ignition energy has been burning them) then they need to be replaced. If they don't seem too bad then use the smallest bit of dielectric (silicone) grease just on the area where the boot engages the ceramic. This should help prevent the problem from happening further.

Installed a Sniper EFI kit onto a freshly rebuilt Pontiac 400 and was trouble free for the first 100 miles. This motor got brand new everything except wiring harness/fuse panel; new Powermaster alternator, PerTronix Flamethrower Distributork, plugs, and wires. Went to back the car out of the shop one day and it would not idle for anything. After going round and round I found that the RPM readout on the handheld display goes crazy reading anywhere from 200-7000 RPM while the engine is just trying to idle. Got with Holley and the pointed me down the RFI rabbit hole. Several tries and "fixes" later i found that if the alternator in unhooked the problem immediately goes away. We took a known good alternator and bolted it onto the Pontiac but the issues unchanged. RFI still present when new alternator is hooked up. With alternator unhooked there is no issue. Since swapping the alternator didnt fix the issue we put the original (but still new) alternator back on the car. I have checked and rechecked every ground i can think of and even added a couple more just to be sure. Ive also fully separated the power circuit from all other wiring up to the fuse block, and separated and insulated all EFI wires present in the engine bay. Last ditch effort, i sent the entire unit back to Holley for testing. Was told the Sniper and the ECU tested good and that the problem was with the install. The ONLY definitive clue is that the RFI goes away when the alternator is unhooked, but replacing the alternator does NOT change the issue. Any other advice or ways i can further pin point the issue? At the end of my roper here so any help is appreciated. Thanks

I have seen individuals in your situation put on two and three brand new alternators of different brands and amperage ratings--and still get the same results every time. So don't waste any more time on that. Instead, I'd check the grounding of the alternator itself. Most alternators are grounded through the mounting bracket to the engine. Start by using an ohm meter and check the resistance between the alternator case and the block. Assuming your ohm meter zeros when you touch the leads together, if it is even one ohm that is more than it should be. Even if it does show good continuity pull not only the alternator but the bracket as well. Sand to bare, clean metal every mating surface between the alternator and the engine block. See what that does for you.

Another action I have heard of people taking is replacing the 1/4-20 air cleaner stud with one made of a non-conductive plastic like nylon or delrin. The air cleaner can act as an antenna too and it sends whatever it picks up straight into the throttle body

...or it can make it worse. The throttle body itself is generally fairly well grounded when bolted into place so, by extension, so are the air cleaner plates. A grounded plate tends to absorb RFI into the ground plane. An ungrounded plate tends to reflect it-- sometimes right down into the ECU. Not a bad idea and definitely worth a try but so much of this is trial and error. What works on one setup can cause problems on another. Others have had success by actually improving the ground of the air cleaner plate by adding a grounding strap. They key is to be persistent and solve the problem, preferably by identifying and removing the source of RFI. Don't give up. :-)

Thank you very much for this article. I am experiencing a faulty TPS which may be due to RFI. The sensor reads normal with key on engine off (goes 0-100% smooth). When I start the car and try to rev the engine the TPS goes to 35% but no further. I should note that I am running a 6.0 truck motor with the high driver side alternator, which happens to be very close to the TPS and IAC on the throttle body. Any advice?

The first thing to do is key the system on, wait about five seconds so that the TPS zero's, and then press the throttle to the floor and watch the TPS. If does the same funky behavior with the engine off then you definitely have a bad TPS.

Even if it acts properly when powered off you might want to just get a new TPS and try it. They aren't that expensive and there is absolutely no down side to keeping a spare TPS in the glove box if that's not the problem. A couple of options for getting one. We offer them at this link, or if you're in a hurry and need one ASAP then stop by an auto parts place and ask for a TPS for a 1990 Cadillac Deville 4.5L V8.

If you swap the TPS and have the same problem then you probably do have an RFI problem. I don't know anything specific to suggest other than what you read above. Good luck!

First of all. Thanks Chris for the feed back regarding my rough running sniper/timing issue even though I bought my sniper through Holley. Every time the alternator (3G) started to charge at 14.2V the timing would go crazy and the unit would hardly run. Take the alternator belt off and all is good. Put a capacitor on the output cable. Same. Get a new alternator. Same. Try a completely different style of alternator. Same. Problem is not the alternator. Move on. Ground different components direct to the battery. Same every time. Last ditch effort. Connect the msd to a separate battery. Same. Connect the msd to a separate battery including the power trigger wire. Problem gone. The msd I was using was I don’t know how old. MSD 6AL. P/n6420 This one is not marked “Digital” Hope this helped someone in the future My sniper was returned to Holley for warranty due to the fan#1 circuit was grounded all the time. Holley did a warranty on it and I have it back While it was gone out I ordered the hyperspark ignition box from u and will be starting the set up and tuning shortly. I have the progressive link kit installed that I bought originally from you. Thanks again Chris

Thanks so much for taking the time to tell us about your problem and solution. What an odd situation! I have had others with similar "alternator-related" problems that never got it solved, even after changing the alternator multiple times and cleaning every connection. But here we see that the alternator was somehow indirectly responsible--that the true culprit seems to have been the old MSD box. Since I never throw out anything that can be re-purposed on another project I can see myself in the same situation. But there have been such gains in technology on these CD boxes over the last few years that anyone with a box more than about 10 years old really needs to consider replacing it before it leaves them stranded. The HyperSpark unit you picked up is going to be a world better. Thanks again for sharing!

I have a similar problem with the sniper and hyperspark on a 68 Chrysler 300. It's being installed by a performance shop and the mechanic says the car starts and runs fine, until the air cleaner is installed. Then it quits. I know they'll find the problem. But I wanted to know if grounding the cleaner might solve the problem?

It never hurts to try but we've seen very limited success from grounding the air cleaner base plate. The problem is that the base plate is not conducting the RFI. If it were then grounding it would solve the problem. Rather, it is acting as a reflector, and grounding it doesn't seem to have much impact on that. It will be necessary to find the source of the RFI and eliminate that.

Just to clarify, the switched +12V wire feeding the coil positive terminal isn't considered "high voltage", is it? It should be fine being in a loom with other sensor wires?

Generally speaking, ground and 12-volt power wires are not emitters of RFI. RFI is not generated so much as a function of the voltage level, but rather as a result of changes in voltage.

That said, one must be careful with the power and ground wires run to the coil. Because of the relatively large changes in amperage loads as the coil fires and recharges, both of these lines can experience rapid variations in voltage. It is for this reason we recommend that one NEVER tie their Sniper's pink switched 12-volt wire to the Coil (+). While it is true that this is a switched 12-volt source, the voltage surges here make it completely inappropriate to use for that purpose.

So I generally avoid putting this into the same loom with sensor wires, particularly any especially low-voltage and susceptible sensors wires. It's the sort of thing you can try if you want (it's not going to "break" anything) but it's the first thing I change if I see RFI on a signal that is run with that wire. Maybe best to just avoid doing that.

I’m currently experiencing the “air cleaner issue” on a brand new SBC build and I’m ready to throw in the towel I’m so frustrated….. RFI is extremely demoralizing and I’m at my wits end with this thing. Glad I found this article though. Guess I have some work to do.

Leave a Comment